- Cyclone Alfred

15 Apr, 2025 - TEN unveils our new brand identity

11 Apr, 2025 - Compression Fitting Failures

14 Mar, 2025 - Understanding How Conduit Sealants Perform in the Presence of Fire

6 Feb, 2025 - Employee of the Year 2024

15 Jan, 2025 - National Work Safety Month 2024

9 Dec, 2024 - Wildlife Mitigation Products

21 Oct, 2024 - Lou's 25th Anniversary

14 Oct, 2024 - TEN HQ is moving

2 Sep, 2024 - Highlights from TENNET 2024

1 Jul, 2024 - The Zero Splice Rule

28 Jun, 2024 - ALE - ClampStar Conductor Repair

31 May, 2024

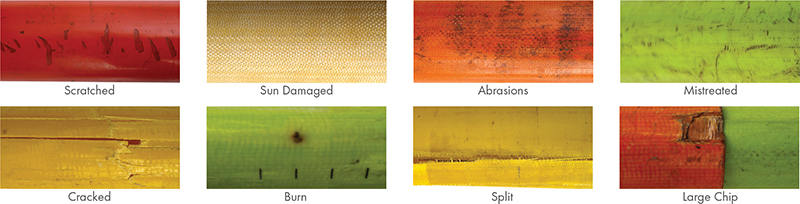

Handy Guide for Fibreglass Stick Maintenance26 Oct, 2021 Fibreglass Equipment Inspection, Cleaning & MaintenanceLive line tools should be visually inspected daily before use for defects such as abrasions, blemishes, burns and surface deterioration. Any defect is cause for rejection as it may impair the dielectric integrity. Rejection does not mean discarding the tool, only removing the tool from service and tagging. Common stick defects to look for

Hot Sticks and Fibreglass Care & MaintenanceFor instruction on how to clean hot sticks, watch our video by scanning or clicking the below QR code. Or download “Advice for the Care and Maintenance of Your Equipment” by clicking this link: https://www.tengroup.com.au/blogs/news/2020/Apr/7/ten_care_and_maintenance For stripping back heavy contamination and prior to re-waxing, use the Hastings All-Purpose, Safe, non-toxic, biodegradable, PH neutral & non-flammable Cleaning Concentrate (10-195). Once the surface has been cleaned thoroughly, it is critical to re-wax the stick. The Polywater® Fibreglass Wax and Buff Kit is a simple, easy to use, one application wipe ideal for this purpose. It should be noted, waxing is best done after a thorough stick cleaning. Use of wax products over contaminated surfaces only locks the dirt in. For spot cleaning the sticks and daily before use, the Polywater® Water Repellent Wipe (Part S-1) that (contains a minimum 60% isopropyl alcohol and silicone) helps clean and restore the water beading properties of the stick. After extended periods of use and exposure to the elements your stick surface may require maintenance. Unless the tool is mechanically damaged your stick may be able to be repaired. For washing booms, use the Polywater® Fibreglass Wash (FGW-640). This replaces the previous (BWC) Boom Wash Concentrate. Download the Stick Inspection and Cleaning Guide Here |

|